PROJECT: Oil Free compressors

A long term existing ACL Engineering customer, involved indirectly and directly with the Water Industry Services, in the supply of Ozone and Oxygen Generating equipment systems, contacted ACL for assistance on a new project.

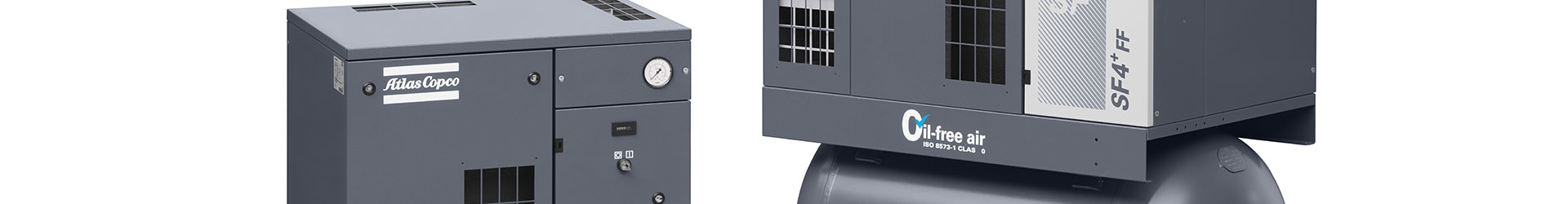

Initial and basic details were for Oil Free compressors (lead & standby) with a – 70’C PDP desiccant air dryer and ancillaries to operate Oxygen Generators.

Details on Atlas Copco’s LF (oil free piston) and SF (oil free rotary scroll) compressors were sent along with other technical equipment details for client and “end-user” review.

ACL were asked to quote for 2 x SF6+ Oil Free Compressors, to operate as lead & standby machines linked to a single, CD+ desiccant air dryer with basic timer control fitted.

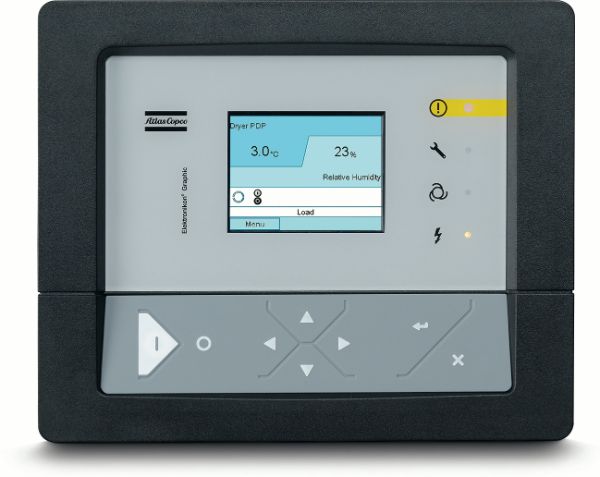

The SF+ machines were selected by the client & end user not only for their Oil Free technology, machine output performance & low noise levels but also due to the machines being fitted with the Atlas Copco Elektronikon starter / controller which would allow certain features and outputs to be used for control & remote monitoring.

Subsequently, a request was made to amend the system to have a second desiccant air dryer – thus giving 100% operation for both duty air compressor / dryer & 100% standby cover for air compressor & air dryer. Further to this, a request was also made for the dryers to have the Atlas Copco, retrofit Pressure Dew Point (PDP) Control fitted so that dryer purge consumption could be reduced to a minimum plus dryer operation could also be monitored.

ACL will commission the plant system following all M & E installation works including control system & monitoring outputs.

Features and Benefits

Pure oil-free air

As there is no metal-to-metal contact between the compression scrolls, there is no need for oil lubrication in the compression chamber. Therefore, the scroll compression principle guarantees high-quality, oil-free air. As a result, the SF compressor is oil-free in every way.

Energy efficiency

The SF scroll compressors, standard equipped with IE3 Premium efficiency motors, are suited for sensitive applications which require flexibility and energy efficiency. Unloaded power consumption is eliminated thanks to the simple

start/stop control. Advanced scroll technology guarantees an optimal free air delivery and low duty cycle applications.

Extremely low noise level

The slow speed of the scroll compression elements ensures that the SF scroll compressors are extremely quiet. Sound levels are as low as 53 dB(a), making the SF the perfect choice for your sensitive working environment.

Simplicity and reliability

The SF scroll compressors stand for simplicity and reliability. The compressor has a minimal number of moving parts, ensuring a long operating life with limited service interventions.

With their integrated design, Atlas Copco’s SF scroll compressors have a minimal footprint and offer easy serviceability.

Proven peace of mind

For over sixty years, Atlas Copco has been leading the industry in oil-free compressed air technology, drawing on vast experience and continuous technological innovations. You can rest assured at all times severe certification and testing procedures are conducted to ensure air is supplied

Atlas Copco Oil-free compressors provide 100% pure, clean air