Energy Efficiency

ACL Engineering undertakes comprehensive energy audits for air compressor systems to evaluate if your existing system is working to maximum potential and at minimum cost. Alternatively, if you’re in the market for a new system, we can design and install a highly efficient, state-of-the-art Atlas Copco system.

Air compressors typically account for from 10-12% and sometimes up to 30% of a factory’s electricity consumption.

Is your compressed air system efficient?

Air compressor systems are a key component in driving many processes at the heart of businesses and industries. Compressed air is used widely throughout UK industry to power equipment such as process machinery, valves, actuators, and hand tools.

Whilst convenient and sometimes essential for safety reasons, it comes with a cost. Compressed air is very expensive to generate, but that cost can be managed through energy efficiency and smart monitoring tools.

STOP WASTAGE!

Leaks – in most cases, reducing leaks is the most important energy-saving action you can take.

Misuse – because it’s so convenient and easy to use, compressed air is often used when it shouldn’t be, for example for cleaning machinery. This is not a cost-effective use of compressed air.

Poor maintenance – a well-maintained system needs less energy to deliver the required pressure.

Poor system control – making adjustments to the system can reduce energy consumption, e.g. by controlling individual compressors with electronic sequential controllers or using an automatic shutdown control.

ENERGY RECOVERY SYSTEMS

Air compressors can be used for heating water for various applications such as heating, hot water and process. This is available through the installation of an integral or stand-alone energy recovery system. The return on investment is impressive – get in touch for more information and to find out about potential savings.

#AIRcheck energy audit

- Data logging

- Analysis of system

- Ultrasonic leak detection

- Recover thermal energy

- Upgrade controls

- Monitor your installation

Compressed air energy-saving solutions

- Carry out a complementary ACL Engineering #AIRcheck audit

- Review use – and misuse. Don’t use where unnecessary or unwarranted

- Consider regular maintenance and servicing, if not already in place

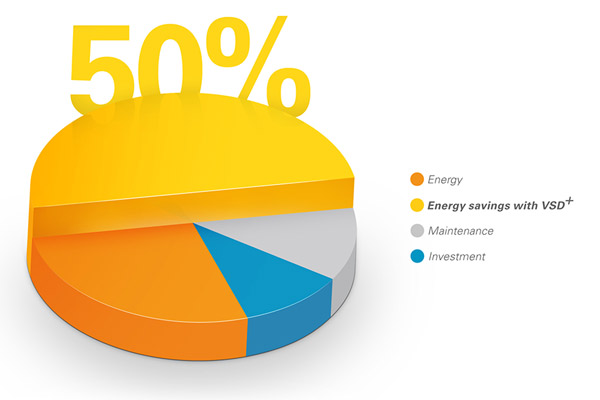

- Install an Atlas Copco Variable Speed Drive (VSD) air compressor

- Reduce the working pressure: every 1 bar = 7% kW savings

- Install an energy recovery system

- Install monitoring software

Speak to our team about Energy efficiency today