NEWS: Air Leak Detection in Air Compressor Systems

Air compressor systems have a multitude of purposes and can be used to power everything from pneumatic tools to conveyor belts, for cleaning, inflating, bottling and food processing amongst other tasks. Because of this they are recognised as an essential resource in many businesses and industries.

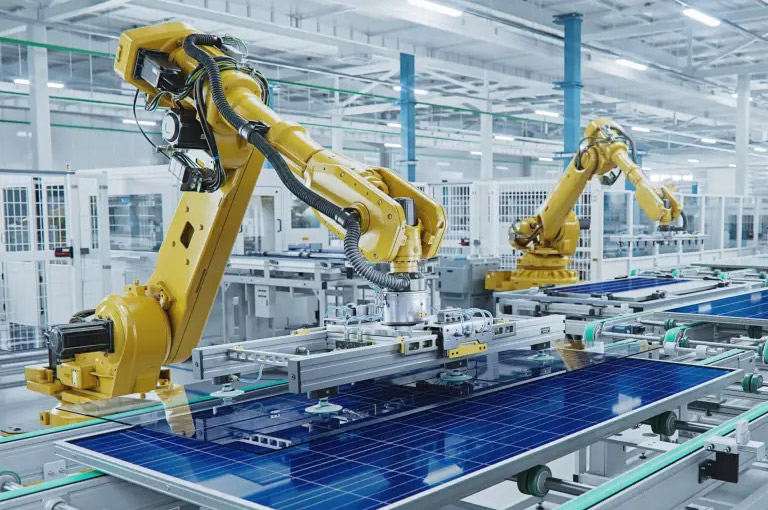

Compressed air as a source of power is versatile and nuanced. It can be tailored and applied to both heavy duty tasks, and fine detailed tasks such as those involved in electronics manufacturing and robotics. Compressor systems do, however, make a certain demand on energy usage, so to ensure maximum return on investment it is important to monitor and maintain the integrity of your system.

The impact of air leaks

An air compressor system consists of not only the compressor itself, but the pipework, joints, seals, valves, condensate traps etc… and endpoints, all of which work together to deliver air ‘power’ to the task in hand. By far the greatest loss of energy is via air leaks in the network that can amount to 20 – 30% of a compressor’s output and sometimes more in a poorly maintained system. Some plants lose as much as 80% of their compressed air due to leaks!

Loss of efficiency and increase in running costs

Leaks can lead to impairment in the system pressure which can make air tools and other equipment less efficient. Meanwhile if your compressor is running at an excess capacity as a result of air losses, this will naturally increase energy usage.

System failure and damage

Air leaks can cause problems with system operations, which can lead to unexpected shutdowns – something that most business want to avoid at all costs. Leaks can cause unnecessary cycling and increased run time, which can decrease the service life of equipment.

Preventing and maintaining air leaks

Inevitably all air compressor systems will have leaks therefore keeping a check on your air compressor system integrity is an ongoing matter. Fortunately there are some excellent tools for the task, the latest of which involves digital air leak detection.

Taking advantage of ultrasonic technology, the handheld device makes it possible to locate and analyse the exact source of each leak and evaluate the size of the loss in litres per minute – and even the real time cost. It can detect even the smallest leak regardless of distance making it possible to evaluate even difficult to reach parts of a network.

Each leak is tagged with an id to assist tracking and note severity. The aim is to map, log, quantify, analyse and apply a cost measurement to each leak to determine the priority of repair works. What’s more, this approach can be performed on a live system with no interruption to production, which is very useful in busy environments, especially where they are in 24-hour operation.

Reporting and repair

An inspection results in a detailed report indicating areas of stress and wear. Issues are ranked in order of priority so that repairs are tackled in the right order to quickly reduce leaks, power loss and energy costs, and also cut CO2 emissions.

Sustainability and the environment

Air loss also impact upon sustainability goals:

“The Carbon Trust estimates that a hole of just 3mm in diameter in a compressed air pipe can create a leak that costs up to £1,000 per year in wasted electricity costs.”

Clearly there are multiple incentives to address air leaks and ensure that they are nipped in the bud. Industry best practice recommends a leak check at least once a year.

Find out more about ACL Engineering’s Leak Detection service here

Photos: courtesy of Beko

To discuss air leak detection in air compressor systems, CALL 01923 249444 OR EMAIL infoacl@aclengineering.co.uk

For unbeatable energy efficiency, ask our team about air leak detection in air compressor systems