NEWS: Oil Free air compressors for sensitive environments

Some manufacturing and industrial environments demand the highest possible air purity to maintain cleanliness and/or sterility and prevent damage to the end products.

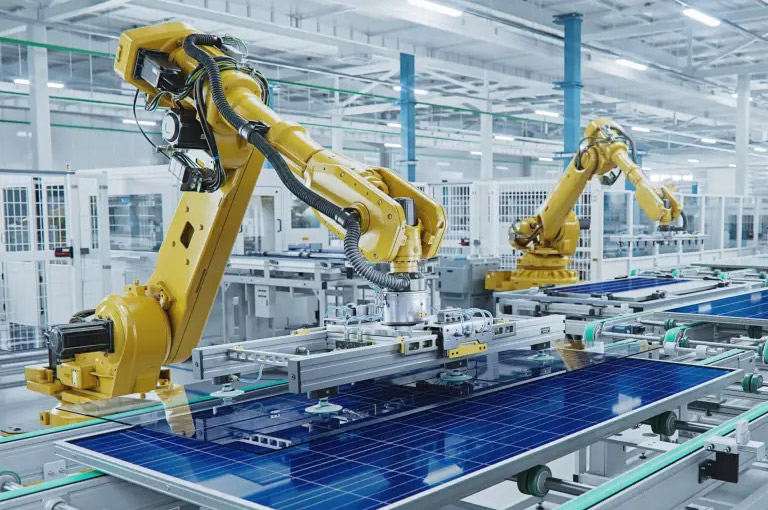

END USAGE WHERE PURITY IS PARAMOUNT

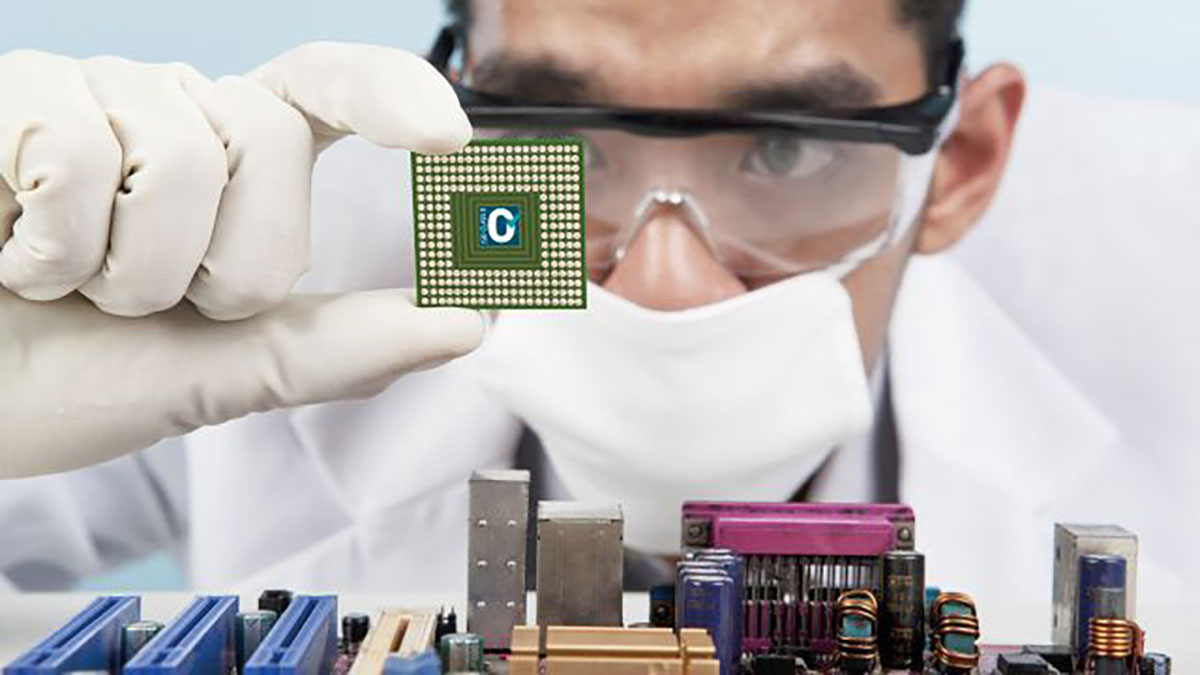

To put this into context consider food and beverage preparation, pharmaceutical production and precision electronics manufacture, to name a few. Utilising oil-based compressors could lead to oil particles finding their way into food affecting flavour and presentation and making the end product unpalatable. Cleanliness and environmental control are absolutely essential in pharmaceutical manufacturing to ensure product safety, quality, and regulatory compliance. In semiconductor and computer component manufacturing, purity is critical, as contamination can lead to malfunctions of the parts, resulting in the waste of costly materials e.g in products like microchips.

ACHIEVING THE HIGHEST QUALITY CLASS ZERO AIR

Oil-free compressors are air compression systems that do not use lubricating oil in the compression chamber. Instead, they rely on alternative methods such as water, Teflon coatings, or self-lubricating materials to reduce friction and ensure smooth operation. Since no oil is used, additional filters and condensate treatment are unnecessary, reducing maintenance compared to an oil-lubricated system.

Atlas Copco is renowned for manufacturing industry-leading compressors, offering a range of oil-free models with screw, scroll, and piston mechanisms to suit various applications.

SCREW COMPRESSORS

Screw compressors, either air-cooled or water-cooled (water-injection is used as the coolant), make up the core of the market. They are ideal for continual-duty operation and deliver best-in-class energy efficiency, reliability and purity. Adding Atlas Copco’s VSD (Variable Speed Drive) technology to the specification will achieve even greater energy savings of up to 35% by eliminating load/no load transition losses.

SCROLL COMPRESSORS

For precision applications scroll compressors utilise frictionless counter-rotating screw elements that do not come into contact in the compression chamber, hence no oil is required. They also have the benefit of being energy efficient, extremely quiet and compact.

PISTON COMPRESSORS

Piston compressors are suitable for smaller applications and lower duty cycles. They offer the best possible air quality in a small footprint. Highly energy efficient and reliable they make premium air purity achievable for smaller capacity needs.

ISO CERTIFIED AIR QUALITY

ISO certified air quality refers to compressed air that meets specific purity standards established by the International Organisation for Standardisation (ISO) under ISO 8573-1. This standard provides a framework for classifying compressed air quality based on three main contaminants:

- Particles (solid contaminants)

- Water (moisture content)

- Oil (including liquid oil, oil aerosols, and oil vapor)

ISO CLASS 0: OIL-FREE AIR

Class 0, the highest standard, represents air purity that exceeds the measured limits of the standard’s testing methodology, or meets custom specifications that are more stringent than Class 1. This class is the cleanest and least risky choice and deemed suitable for highly sensitive manufacturing environments such as pharmaceuticals, electronics, food and beverage.

ISO CLASS 1: TECHNICALLY OIL-FREE AIR

This class allows for a certain level of oil contamination (up to 0.01 milligrams per cubic meter (mg/m3)) to be introduced into the compressed air stream, which then needs to be filtered and removed downstream. Known as ‘technically oil-free’ it nevertheless results in a higher chance of contamination and is suited for less stringent environments where high air purity is still required but low oil content is acceptable.

THE OIL-FREE ROUTE TO SUCCESS

Where ISO Class 0 air-purity is of the highest priority, oil-free compressors are the solution. While they are typically more expensive than their oil-lubricated counterparts at the outset, but the reduced ancillary equipment involved – such as filters and dryers – mean that over time, maintenance costs are less. Choosing energy-efficient models helps businesses to keep energy costs down and achieve sustainability goals.

TO DISCUSS OIL FREE COMPRESSORS, CALL 01923 249444 OR EMAIL infoacl@aclengineering.co.uk

Have a demand for high air purity in your manufacturing processes?